Water Treatment Plant

Leading Manufacturers, Wholesaler, Trader, Distributor of Activated Carbon Filter, Demineralisation Plant, Dual Media Filter, Effluent Treatment Plant, Iron Removal Filter, Reverse Osmosis Plant, Sewage Treatment Plant and Water Softener Plant from Mohali.

| Business Type | Manufacturer, Supplier, Trader, Distributor |

| Material | Mild Steel |

| Shape | Round |

| Voltage | 220V |

| Finishing | Powder Coated |

| Warranty | 1 Year |

| Packaging Type | Carton Box |

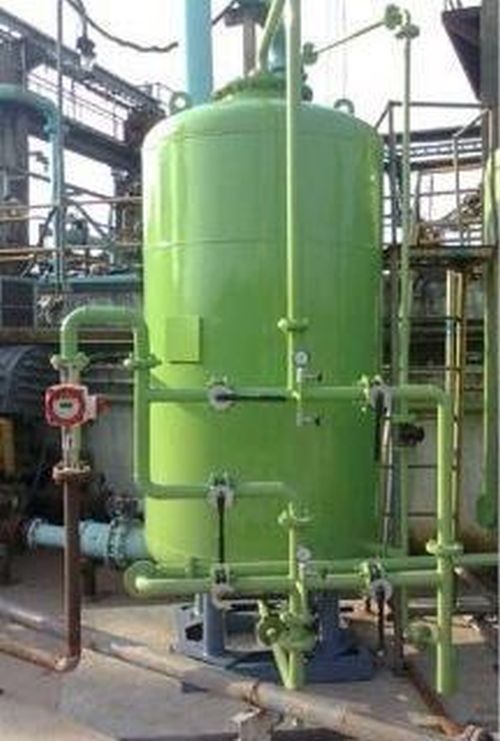

SHIMMER Activated Carbon Filters are intended to remove free residual chlorine and toxic organic compounds from water like pesticides and heavy metal organic compounds.

For removal of odour, organic matter and traces of oil, peat based activated carbon with larger pore size can be supplied on request.

FEATURES

- Filters are compact and easy to install and maintain.

- The filters can tolerate any variation or shock loads in free residual chlorine unlike chemical dosing systems which require constant monitoring and adjustment of dosages.

- Pressure gauges at inlet and outlet are provided to measure pressure gauges across the unit. Filter backwash is carried out by reversal of flow.

Applications: -

The Activated Carbon filter is an ideal choice for all applications where a conventional sand filter is used.

- Raw Water Treatment Process.

- Drinking Water.

- Side Stream Filtration for cooling water.

- Filtration Process in Industries.

- Pre-Treatment for Membrane systems.

- Swimming Pool water Filtration.

- Filtration in Tertiary waste water treatment.

Features

- Filters are compact and easy to install and maintain.

- The filters can tolerate any variation or shock loads in free residual chlorine unlike chemical dosing systems which require constant monitoring and adjustment of dosages.

- Pressure gauges at inlet and outlet are provided to measure pressure gauges across the unit. Filter backwash is carried out by reversal of flow.

RANGE OF PRODUCT MODEL AVAILABILITY- Activated Carbon Filter is comprises of Mild Steel /MSRL/SS/FRP Pressure Vessel, Frontal piping wok with manual / Automatic - multi port valve/ butterfly valve / conventional valves for easy operation and control. Available from 1 m3/hr. to 100 m3/hr.

| Business Type | Manufacturer, Supplier, Trader, Distributor |

| Voltage | 220V |

| Frequency | 50Hz, 60Hz |

| Driven Type | Voltage |

| Warranty | 1yrs |

| Sterilizing Rating | 99.99% |

| With/Without | MB or DGT |

SHIMMER Two Bed Deionisers consist of FRP/MSRL pressure vessels containing ion exchange resins (commonly referred to as cation and anion exchange resins). The vessels are provided with strainers at the bottom. This not only ensures the exchangers are retained within the vessels but also uniform distribution, flow of water and regenerant takes place in the unit. The unit is fitted with all the necessary piping and individual valve for carrying out the various operations like service, injection and rinse. Regenerant tanks, one each for acid and caustic soda are provided from which measured quantities of regenerant solutions are injected into the unit by means of hydraulic ejectors. A conductivity indicator with cell is provided for continuous measurement of treated water purity.

The two bed deioniser units can be supplied with optional extra equipment such as a degasser to handle certain types of raw water with high amount of alkalinity. The cation exchanger converts alkalinity present in raw water to its equivalent acid, i.e. carbonic acid. The anion exchanger absorbs this along with other acids in cation exchanger treated water. Where water has a high alkalinity the ionic load on the anion can be brought down by using another method to remove carbonic acid. Carbonic acid is unstable and readily breaks down into carbon dioxide and water. The carbon dioxide can be removed mechanically by means of a degasser.

Features

- Easy to install and maintain.

- High Capacity cation exchange resin in sodium form.

- Customised design.

- Less maintenance and operational cost.

Applications: - The Demineralisation Plant is an ideal choice for removal of hardness from raw water for all applications.

- Boiler feed water

- Process water in textile mills

- Beverage manufacture

- Laundry and air conditioning plants

- Cooling tower make-up water

- Jacket cooling

- Hospitals, hotels

- Jacket cooling

RANGE OF PRODUCT MODEL AVAILABILITY- Demineralisation Plant is comprises of MSRL/FRP Pressure Vessel, Frontal piping wok with manual / Automatic - multi port valve/ CIEL valve / conventional valves for easy operation and control. Available from 1 m3/hr. to 100 m3/hr.

| Business Type | Manufacturer, Supplier, Trader, Distributor |

| Material | Mild Steel |

| Shape | Round |

| Voltage | 220V |

| Finishing | Polished |

| Warranty | 1 Year |

| Packaging Type | Wooden Box |

| Available from | 1 m3/hr. to 100 m3/hr. |

SHIMMER Dual Media Filter is used for removal of suspended solids, turbidity and some part of color and odor from Water & Wastewater. We, at SHIMMER offer Series of filters at a low cost, reliable and highly efficient way to filter your water.

Removes the Dual Media Filter

- Iron

- Manganese

- Turbidity

- Suspended solid

- Arsenic

- Fluoride

Applications: -

The Dual Media filter is an ideal choice for all applications where a conventional sand filter is used.

- Raw Water Treatment Process.

- Drinking Water.

- Side Stream Filtration for cooling water.

- Filtration Process in Industries.

- Pre-Treatment for Membrane systems.

- Swimming Pool water Filtration.

- Filtration in Tertiary waste water treatment.

RANGE OF PRODUCT MODEL AVAILABILITY

Dual Media Filter is comprises of Mild Steel /MSRL/SS/FRP Pressure Vessel, Frontal piping wok with manual / Automatic - multi port valve/ butterfly valve / conventional valves for easy operation and control.

Available from 1 m3/hr. to 100 m3/hr.

| Business Type | Manufacturer, Supplier |

| Material | Mild Steel |

| Application | Water Recycling |

| Power Source | Electronic |

| PH Value | 7.5 - 8.5 |

| Usage | Liquid Filter |

| Automation Grade | Automatic |

SHIMMER Effluent Treatment covers the mechanisms and processes used to treat water that have been contaminated in some way by anthropogenic industrial or commercial activities prior to its release into the environment or its reuse. Effluent treatment plants may also be utilized effectively for a cluster of small-scale industrial units. ETPs can be based on physio-chemical or biological treatment, in presence of air (aerobic) or in the absence of air (anaerobic). SHIMMER provides solutions on a turnkey basis right from conceptualization to commissioning. Our solutions related to ETP include:

- Primary Treatment (Coagulation, flocculation and clarification)

- Secondary Treatment for aeration, clarification and disinfections

- Tertiary Treatment for colour removal and reduction of TDS

- Recycling of water

We also manufacture ETP based on anaerobic biological treatment which utilize the concept of Up flow Anaerobic Sludge Reactor (UASBR). The sludge blanket is comprised of microbial granules (0.5-2.0 mm diameter), that, because of its weight, resist being washed out in up flow stream. The microorganisms in the sludge layer degrade organic compounds. as a result, gases such as methane and carbon di oxide are released which after purification can be used as energy (biogas).

Application

- Food Processing Units

- Mining

- Pharmaceutical Units

- Electroplating Units

- Refineries

- Distilleries

- Textile Houses

- Fisheries

- Laundries

- Slaughter Houses

| Business Type | Manufacturer, Supplier, Trader, Distributor |

| Material | Stainless Steel |

| Voltage | 220V |

| Finishing | Polished |

| Warranty | 1 Year |

| Operating Type | Automatic |

| Available from | 1 m3/hr. to 100 m3/hr. |

SHIMMER Iron Removal Filters are designed to remove the Excess Iron content present in the feed water with minimum pressure drop.

These filters remove up to 10 ppm of inorganic iron from water, reducing this to an average of 0.3 ppm. They do not use chemicals and can be backwashed with only water/treated water. The media remains effective as long as the feed water contains dissolved oxygen to the extent of its natural solubility.

Applications: -

- The Iron Removal filter is an ideal choice for all applications where a conventional sand filter is used.

- Drinking water for residential colonies and commercial complexes

- Pre-treatment for industrial water treatment plants

- Food processing, beverages and mineral

Features

- Increased solid removal

- Ensures processing stability

- Hexagonal tube shape provides better tube drainage

- Better drainage reduces blockage cleaning

- Less tube blockages increase effective settlement rates

- In-tube contact flocculation

RANGE OF PRODUCT MODEL AVAILABILITY- Iron Removal Filter is comprises of Mild Steel /MSRL/SS/FRP Pressure Vessel, Frontal piping wok with manual / Automatic - multi port valve/ butterfly valve / conventional valves for easy operation and control. Available from 1 m3/hr. to 100 m3/hr.

| Business Type | Manufacturer, Supplier, Trader, Distributor |

| Application | Industrial |

| Finishing | Polished |

| Driven Type | Electric |

| Available from | 0.2 m3/hr. to 40 m3/hr |

| Design | Standard |

SHIMMER RO Plants are designed for an optimized solution to customer’s requirements in terms of output water quality, water efficiency, energy efficiency, maintenance costs and capital costs. While plant sizes and input water quality are the variables always, optimizing quality, efficiencies and costs is an invariably admired constant at SHMMER. These systems remove 90-98% of total dissolved solids from brackish water and sea water. Our RO Plants are all time retrofit ready.

Applications: - The RO Plant is use for removal of dissolved salts from raw water for all applications.

- Purified Water (PW) for pharmaceuticals

- Water for electrical conductor circuits

- Process Water for manufacturing units

- Drinking & Mineral Water

- Dialysis

- Boiler feed water

- Process water in textile mills

- Bio-technology

- Food and Beverage processing industry

- Cooling tower make-up water

- Hospitals, hotels

FEATURES

- Easy to install and maintain.

- Product flow rate 0.2 – 40 m3/hr.

- Salt rejection ranges from 90 – 99% depending upon feed water composition.

- Product recovery ranges from 55 – 75%.

- All components are of proven quality.

- Customised design.

- Less maintenance and operational cost.

RANGE OF PRODUCT MODEL AVAILABILITY- RO Plant is comprises of FRP/SS Pressure Tube, Skid – MS/SS, Pre filter – PP/SS, Frontal valve & piping wok – uPVC/SS for easy operation and control. Available from 0.2 m3/hr. to 40 m3/hr.

| Business Type | Manufacturer, Supplier |

| Weight | 1000-2000kg |

| Automatic Grade | Automatic |

| Power | 1-3kw |

| Driven Type | Electric |

| Warranty | 2years |

SHIMMER Sewage treatment is the process of removing contaminants from wastewater generated from industrial or domestic sewage using physical, chemical, and biological processes. Its objective is to produce an environmentally safe fluid waste stream and a solid waste (or treated sludge) suitable for disposal or reuse usually as manure. The treated water after tertiary treatment can be used for cooling towers, horticulture, flushing and washing.

SHIMMER offers various advance technologies with low foot print as per customer requirement. The prefabricated STPs from 10 KLD to 100 KLD are ideal for applications where time and area are the essence of the project. Higher capacity STPs require civil construction.

- We also offer the Packaged/compact STP.

- Technologies offered for STP’s are FAB, MBBR, SBR, Constructed Wetland, MBR etc. or others as per client requirement/ site conditions.

- Design of recycling and reuse concepts by providing tertiary polishing treatment to treated sewage water for plant reuse applications of gardening/ flushing/ reuse in cooling tower makeup/ floor washing etc.

Applications

- Industrial Sanitation

- Housing complexes

- Townships

- Hospitals

- Shopping Malls

- Colleges

| Business Type | Manufacturer, Supplier, Trader, Distributor |

| Application | Cleaning Water |

| Weight | 100-1000kg |

| Voltage | 220V |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Available from | 1 m3/hr. to 100 m3/hr |

SHIMMER is a leading brand in the field of Water Softeners. This water softening Plants are based on the proven ion exchange process. The Water Softeners are simple in operation, highly efficient and compact units designed to produce soft water efficiently and economically. The Water Softeners are charged with a high capacity polystyrene bead cation exchange resin in sodium form. When hard water passes through this resin column, the hardness forming calcium and magnesium salts are replaced with sodium salts which do not carry any hardness properties. This softening process is continuous until the material is exhausted of sodium salts when it is regenerated with a solution of common salt.

Applications: -

The Softener plant is an ideal choice for removal of hardness from raw water for all applications.

- Boiler feed water

- Process water in textile mills

- Beverage manufacture

- Laundry and air conditioning plants

- Cooling tower make-up water

- Jacket cooling

- Hospitals, hotels

- Jacket cooling

FEATURES

- Easy to install and maintain.

- High Capacity cation exchange resin in sodium form.

- Customised design.

- Less maintenance and operational cost.

RANGE OF PRODUCT MODEL AVAILABILITY- Softener Plant is comprises of Mild Steel/MSEP/MSRL/FRP Pressure Vessel, Frontal piping wok with manual / Automatic - multi port valve/ butterfly valve / conventional valves for easy operation and control. Available from 1 m3/hr. to 100 m3/hr.